|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

||

October, 1996

Found Objects

| [L10] Aircraft Skin (TIGHAR Artifact 2-2-V-1) | ||

| Date Found: | October 1991 during TIGHAR’s NIKU II expedition. |  |

| Materials analysis: | NTSB | |

| Report date: | March 5, 1990 | |

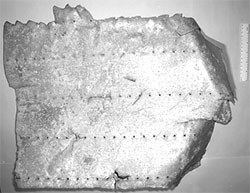

| Description: | This is a sheet of 0.032 Alclad measuring roughly 23 inches by 19 inches. There are four rows of evenly spaced 3/32 inch diameter rivet holes with a 1 inch pitch (space between centers) and one row of 5/32 inch diameter rivet holes with a nominal pitch of 1.25 inches along its long dimension. There is no line of rivet holes across the width of the sheet. The rows of rivet holes are not parallel but show a slight convergence. Nominal spacing between rows is 4.25 inches at one end of the sheet and 1/8 to 1/4 inch closer at the other end. One rivet is still present. The length of the undeformed rivet shank (distance between the manufactured head and the formed head) indicates that the skin was previously attached to an underlying member approximately 0.06 inch in thickness. The faint outline of 1/2 inch tall letters “AD” are present on what was the exterior surface of the skin. | |

| Condition: | The sheet is bounded by fractures on all four edges (no manufacturer’s cut is present) and has a pronounced curvature across the short dimension. On one side the fracture runs generally along the line of 5/32 rivet holes. The fracture intersects all of the 5/32 inch diameter holes except for three unfractured holes which are unevenly spaced. The skin around the 3/32 inch diameter rivet holes is dimpled inward toward the concave side of the sheet suggesting that the surface was area loaded from the concave side while the rivets and underlying structure were intact. Scratch marks on the interior (concave) surface adjacent to some of the rivet holes suggests the further removal of underlying structure by prying with a hand tool. Post separation abrasion and erosion damage has obliterated the fracture faces and, in the opinion of the NTSB, positive determination of the modes of fracture can not be established. However, the NTSB did note that the fracture geometry along the line of 5/32 rivet holes is consistent with tearing separations in both directions away from the area of the intact holes. Deformation adjacent to the fracture along one edge of the sheet indicated that it had been folded 90 degrees toward the convex side at least twice prior to separation. The only place on the sheet exhibiting significant corrosion is an area roughly 1.5 inches in diameter located immediately adjacent to the “tab” with the three undamaged 5/32 rivet holes. The corrosion originated on the interior surface of the sheet and has perforated the exterior surface in three pinpoint-sized locations. | |

| Identification: | This is a forcibly removed section aluminum which was once part of an airplane skin. The aircraft was of all-metal construction and was manufactured in the United States, probably before 1939. The surviving rivet is an AN 455 AD 3/3. The head style, known as the “brazier” head, was replaced in most applications by the “universal” head (AN470) sometime after 1940. The letters “AD” noted on the exterior (convex) surface are the last two letters in the word ”ALCLAD” which was stamped onto the aluminum in red ink at the time of manufacture by Alcoa Aluminum as part of the product labeling. Complete examples of this same size and style of lettering (ALCLAD 24S T3) have been noted on aluminum used in repairs or modifications to two surviving Lockheed 10s: c/n 1015, recently rebuilt as a replica of Earhart’s aircraft and currently registered NX72GT, and c/n 1052 in the New England Air Museum collection. Similar labeling has also been found on a small patch on the nose of a Douglas C-47 in the Dover AFB Museum collection. The font, or type style, of the lettering does not appear to match any of the styles used by Alcoa for aluminum manufactured during or after World War II. The fact that the lettering is not aligned with the grain of the metal indicates that the labeling was hand-stamped, a practice replaced by rolled-on labeling when aluminum production boomed after 1939. | |

| Commentary: | This is, by far, the largest and most complex aircraft artifact found on Nikumaroro to date. It is also the most controversial. The skin’s material components, dimensions and rivet pattern are similar, but not identical, to some portions of the Lockheed Model 10. TIGHAR initially noted the artifact’s similarity to the underside of the Electra just forward of the cabin door and attributed the differences to changes made when the Earhart aircraft was repaired following its March 20, 1937 accident in Hawaii. Critics correctly pointed out that such structural changes could not have been made without a wholesale re-engineering of the aircraft for which there is no evidence. Subsequent research has identified another location on the Earhart aircraft which seems more promising. |

|